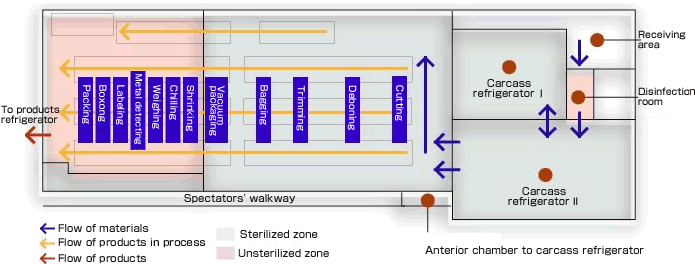

Meat center

Himeji Meat Center

- Carcass Sterilizing

-

On acceptance, carcasses are to be sent to the separated sterilization room, to be sterilized one by one. The sterilization in a separated room not only reduces bacteria but also prevents cross-contamination. Reduction of bacteria prevents the formation of bubbles when meat is packed.

- Carcass Refrigerator

-

By preventing direct exposure to the outer air, the carcass refrigerator shuts out bacteria. With a stringent control system, it has a capacity of controlling carcasses of 300 head regularly.

- Hygienic Processing Room

-

Himeji Meat Center is a processing plant equipped with stainless steel devices and a stringent sanitary management system that continuously controls its temperature and humidity. With the ability of fabricating and deboning 1 head of cattle every 15 minutes, it complies with the traceability system.

- Distribution

-

Portion meat labels of our meat products show place of origin, breed of cattle and identity number of each product.